Other Components

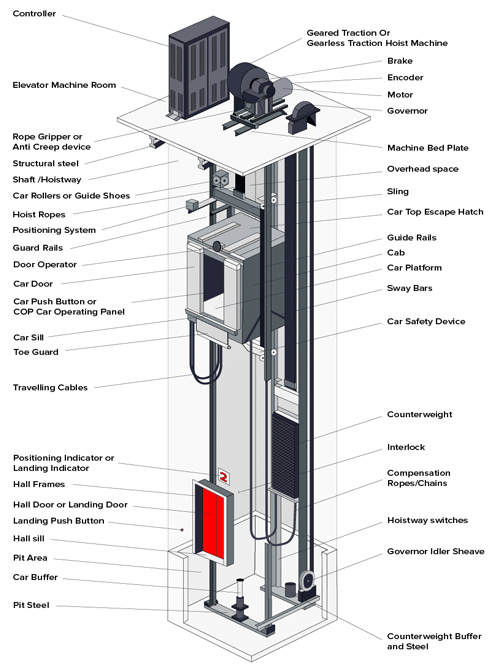

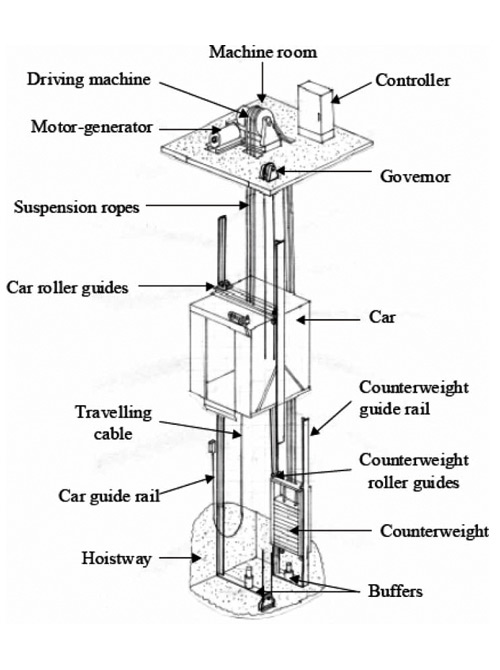

Hoistway

The space enclosed by fireproof walls and elevator doors for the travel of one or more elevators, dumbwaiters or material lifts. It includes the pit and terminates at the underside of the overhead machinery space floor or grating, or at the underside of the roof where the hoistway does not penetrate the roof.

Guide Rails

Steel T-shaped or formed sections with guiding surfaces installed vertically in a hoistway to guide and direct the course of travel of an elevator car and elevator counterweights.

Buffers

The buffer is an apparatus located at the bottom of elevator designed to protect people. Buffers can stop a descending car by accumulating or dissipating the kinetic energy of the car.

Speed governors

Most elevators have an entirely separate speed-regulating system called a governor, which is a flywheel with mechanical arms built inside it. Normally the arms are held inside the flywheel by springs, but if the lift moves too fast, they fly outward, pushing a lever mechanism that trips one or more braking systems. First, they might cut power to the lift motor. If that fails and the lift continues to accelerate, the arms will fly out even further and trip a second mechanism, applying the brakes. Some governors are entirely mechanical; others are electromagnetic; still others use a mixture of mechanical and electronic components.

The safety brake

Everyone who’s ever travelled in an elevator has had the same thought: what if the cable holding this thing suddenly snaps? Rest assured, there’s nothing to worry about. If the cable snaps, a variety of safety systems prevent an elevator car from crashing to the floor.

Each car ran between two vertical guide rails with sturdy metal teeth embedded all the way up them. At the top of each car, there was a spring-loaded mechanism with hooks attached. If the cable broke, the hooks sprung outward and jammed into the metal teeth in the guide rails, locking the car safely in position.